Due to the increasing pressure to provide product quality, customers have higher and higher expectations for manufacturing quality, coupled with the high cost of poor manufacturing quality: (rework, scrap, product failure, recall...). To be competitive in the global market, high quality standards must be established. The demand for industrial NVH quality test systems is rising, and industries such as motors, internal combustion engines, gearboxes, axles and turbochargers have more and more demands for NVH quality test at the end of the production line.

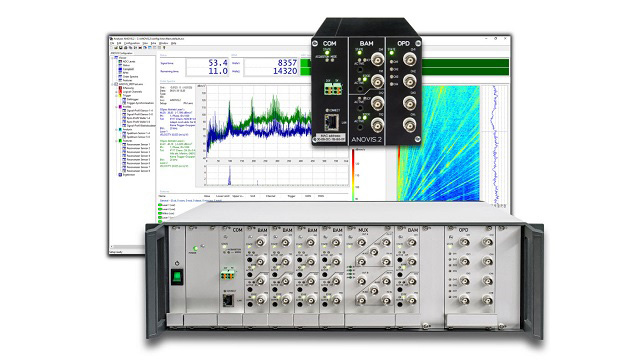

Simcenter™ Anovis™ system provide customers with a perfect solution for product offline testing with market competitiveness. The system is applied to the NVH quality inspection and fault diagnosis of the production line terminals of motors, internal combustion engines, gearboxes and other parts in the automobile and home appliance industries; crack inspection of body parts; assembly process monitoring such as wiring harness plugs and component connections. The hardware and data acquisition and analysis software of the entire system are all developed by Siemens industrial software, which fully guarantees the integrity of the system and the seamless compatibility of test and analysis data.

Based on the Siemens Simcenter Anovis software and hardware combination, combined with Siemens and customers to complete the deployment, implementation, training, technical service and technology transfer of the production line noise and vibration test system.

Case 1: EOLT of steering motor

Fully automatic production line terminal test

Does not affect the production cycle

Detect product NVH quality

Application in high speed motor system

With the NVH level provided, minor noise problems can also be found

Case 2: Crack detection of electric power steering’s belt pulley

Percussion detection by electronic hammer

Broadband microphone records noise data

Fully automatic 100% production test, within 6s you can determine whether the product has passed

Case 3:The glass fiber rod broke during the crimping process

Machine vibration analysis, online real-time evaluation of product qualification, emergency stop if damage occurs

Industry 4.0: Link the data from the production machine (temperature, pressure coordinates, feed rate, etc.) with the quality data of the produced goods

Process monitoring: such as the vibration characteristics of the orthogonal cutting machine during operation, traditional temperature testing, image processing