Ameism&PreScan Engineering

Purpose

This co-simulation between Simcenter™ Amesim™ and Simcenter Prescan™ illustrates both:

the unique Simcenter Prescan and Simcenter Amesim combination for a complete and accurate ego vehicle digital twin,

the importance of the chassis model fidelity to correctly predict the risks of an ADAS intervention, in this case an inopportune AEBS triggering.

In this engineering, a few mildly accident prone elements of the scenario (lowish grip, highish lateral acceleration, confusing road configuration, poorly stopped truck), quite mild taken one at a time, combine into an extremely challenging situation.

When it is such a combination that makes the situation dangerous, a simple chassis model, commonly used to evaluate ADAS in sensor centric situations, which does not take into account the various physical couplings (lateral with longi and vertical) nor the subsystems interactions, will fail to predict the vehicle behavior.

The preview below contrasts the outcomes predicted by the low (left) and high (right) fidelity models.

Figure 1: AEBS triggers in turn - low (left) vs high (right) fidelity model.

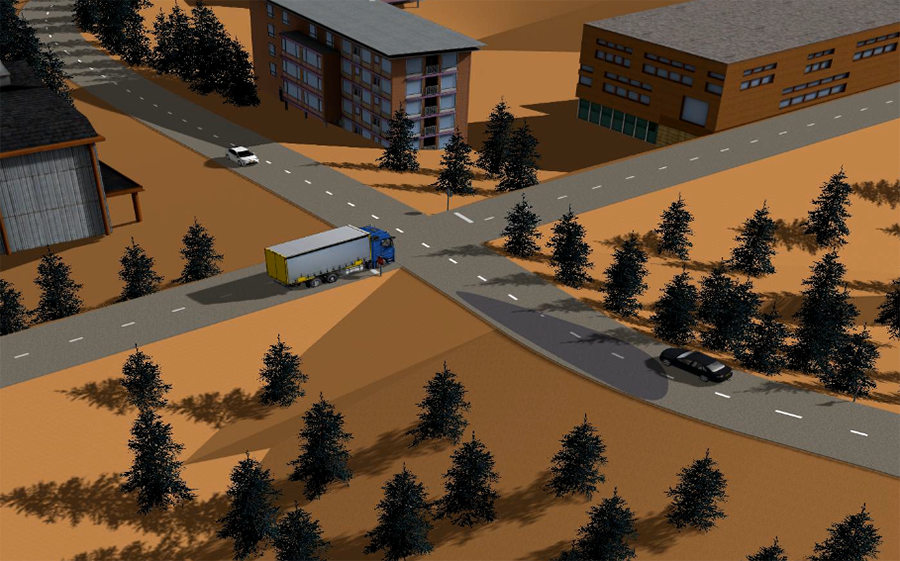

Figure 2: Scenario overview - ego car is the black car on the right.

The overall scenario is about an ego car driven by a sporty driver at 70km/h, climbing a mountain slope before a right corner he will negotiate at a 5 m/s2 lateral acceleration. In some versions of this scenario, a truck will be coming from a left secondary road, decelerating before a stop sign placed after a shallow curve. This is challenging for the AEBS, not because of visibility issues, but because the truck seems to be on the trajectory of the car.

The ego car AEBS triggers inopportunely due to this wrong understanding of the situation. The emergency braking will occur on a drying (on the right side of the road) and still very wet portion of the left side of road, thus creating a mu-split situation.

This will cause cascading interactions between the AEBS, ESP and ABS systems.

There are four different circumstances as follow:

Lower fidelity vehicle dynamics, with no truck stopping, and thus no AEBS inopportune trigger

Higher fidelity vehicle dynamics, with no truck stopping, and thus no AEBS inopportune trigger

Lower fidelity vehicle dynamics, with truck stopping and AEBS inopportune trigger

Higher fidelity vehicle dynamics, with truck stopping and AEBS inopportune trigger

Figure 3: Sum-up chart describing the four cases

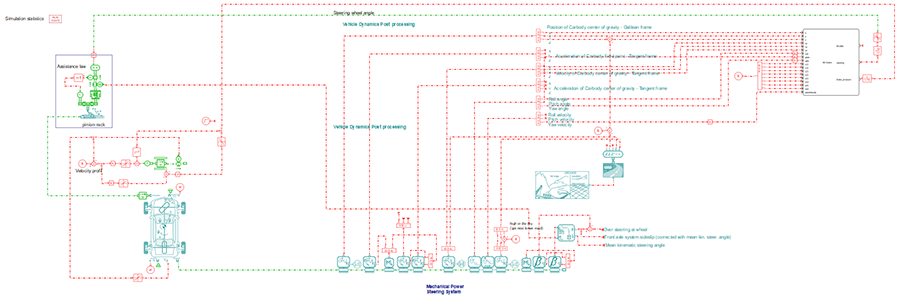

Figure 4: Lower fidelity vehicle dynamics sketch

The lower fidelity model contains a 2 DOF bicycle chassis model extended with the body roll DOF, a simple piloted-friction mass 1D model for the ego car braking and an altitude profile to climb the hill. The tires models are linear in side slip angle and don't have any drift saturation. This model's limitations are as follow:

No heave vertical load taken into account

No longitudinal load transfer

No coupling for tire lateral and longitudinal loads

Not adequate for ABS and ESP coupling

On the other hand, this chassis and tire model combination can be much faster than real-time and is relevant for moderate lateral accelerations situations on flat roads.

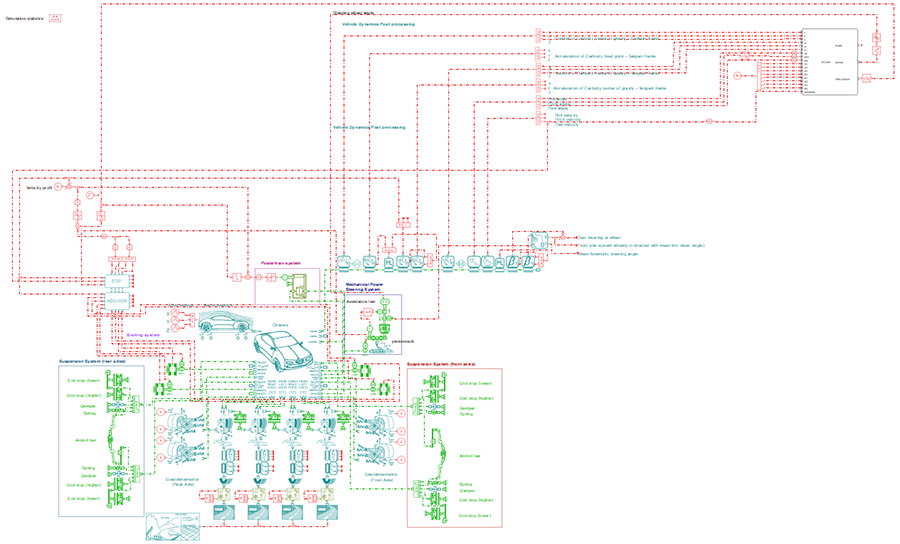

Figure 5: Higher fidelity vehicle dynamics sketch

The higher fidelity model contains a 15 DOF chassis model with Pacejka tires. This chassis model takes into account kinematics and compliance, suspensions non-linearities, load transfers and wheel loss of contact with the ground. The Pacejka model is a well recognized industry standard, taking into account local grip modulation, lateral-longitudinal coupling and significantly transient situations. This chassis and tire model combination is thus valid for higher, coupled accelerations profiles involving transients maneuvers, making it an excellent mean to assess most safety and comfort scenarios. It is faster than real-time standalone in Simcenter Amesim and in some cosimulation contexts.