Innovate products without compromising time-to-market and quality by using the leading integrated, scalable system simulation platform. Simcenter™ Amesim™ software allows system simulation engineers to virtually assess and optimize the performance of mechatronic systems. This will boost overall systems engineering productivity from the early development stages until the final performance validation and controls calibration.

Simcenter Amesim includes ready-to-use multi-physics libraries combined with application and industry-oriented solutions that are supported by powerful platform capabilities, to let you rapidly create models and accurately perform analysis. It is an open environment that can be integrated into your enterprise processes. You can easily couple the software with major computer-aided engineering (CAE), computer-aided design (CAD) and controls software packages, interoperate it with the Functional Mock-up Interface (FMI), Modelica®, and connect it with other Simcenter solutions, Teamcenter and Excel.

Electrical System Simulation

Simulate electrical and electromechanical systems from concept design to control validation.Simcenter Amesim helps optimize the dynamic performance of mechatronic systems, analyze power consumption, design and validate control laws for electrical devices for the automotive, aerospace, industrial machinery, and heavy equipment industries.

Using Simcenter Amesim, you can investigate various electrification architectures of conventional vehicles, and virtually assess the impact of electric subsystems on the global performance of electric and hybrid electric vehicles. You can also address the challenge of developing more electric aircraft and future electrified propulsion systems.

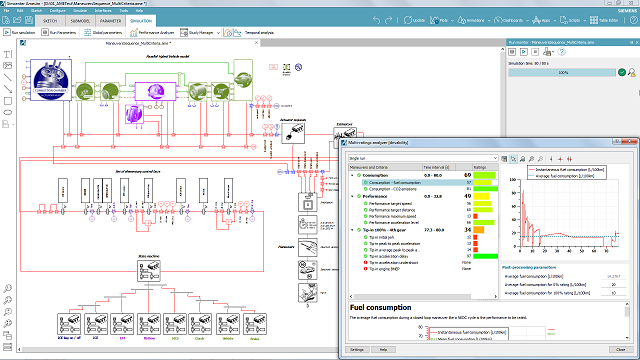

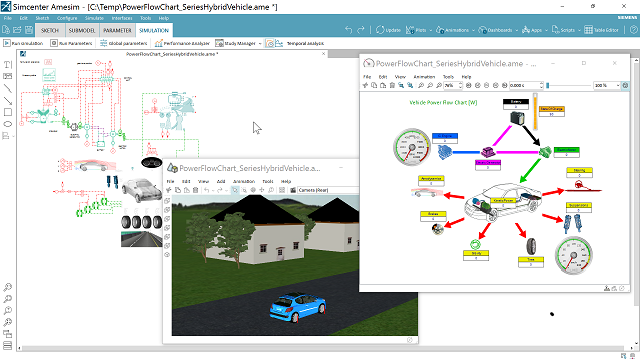

Electrified Vehicle Simulation

Master the engineering complexity of vehicle electrification. Simcenter Amesim offers the required modeling level to simulate all critical subsystems. Whether you deal with battery sizing or electric machine design, you can benefit from efficient modeling workflows to support your engineering effort from architecture creation to integration, including detailed design.

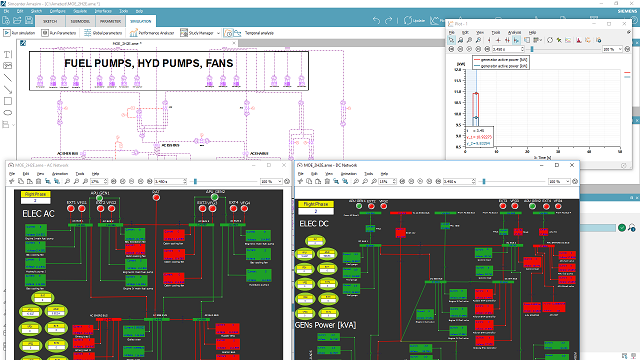

Aircraft Electrical System Simulation

Create a more electric aircraft by optimizing its electrical network and accounting for thermal integration. Simcenter Amesim helps you design reliable generators, electromechanical and electro hydrostatic actuators, and analyze the impact of network reconfiguration in case of failure. Using cosimulation with Simulink®, you can integrate generator control units with high-fidelity multiphysics models. Preprocessing and postprocessing tools, like EHA and EMA parameter optimization, fast Fourier transform (FFT), and linear analysis features, help succeed in certification tests.

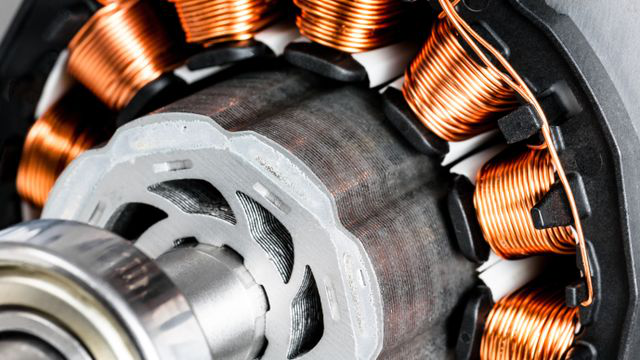

Electrical System Modeling

Benefit from off-the-shelves models for batteries, fuel cells, power converters, linear actuators, and electric motors to build any kind of electrical device architecture. Using the Simcenter Amesim multi-physics, multi-level, scalable, and flexible approach, you can address many engineering issues like the design of the thermal management system, the assessment of the system performance, or efficiency with realistic mechanical or hydraulic loads, as well as the design and validation of your control.

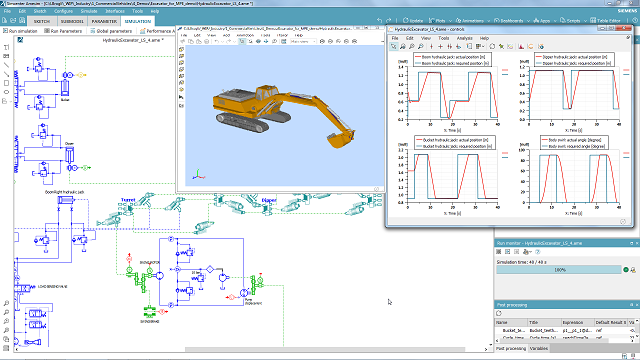

Fluid System Simulation

Optimize the dynamic behavior of hydraulic and pneumatic components while limiting physical prototyping to the strictly necessary. With a wide choice of components, features and application-oriented tools, Simcenter Amesim allows you to model fluid systems for a wide range of applications such as mobile hydraulic actuation systems, powertrain systems or aircraft fuel and environmental control systems.

Simcenter Amesim provides you with comprehensive component libraries to support occasional and expert users when modeling fluid systems, from functional to detailed models. The seamless communication between libraries and the accurate modeling of physical phenomena enable the design of any fluid system and the coupling with controls and other related systems in a single platform.

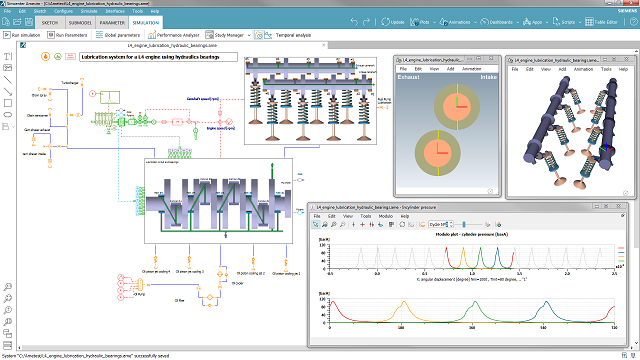

Powertrain Subsystem Simulation

Accelerate the design of your valvetrain, cranktrain, fuel injection, lubrication and cooling systems. Simcenter Amesim allows you to size your components, assess and optimize your system efficiency and validate your control strategies. You will be able to prepare the integration of your subsystem within the powertrain environment by evaluating the interaction between the different subsystems and with the combustion chamber, and analyze the impact of your subsystem design on engine performance, fuel economy or emissions.

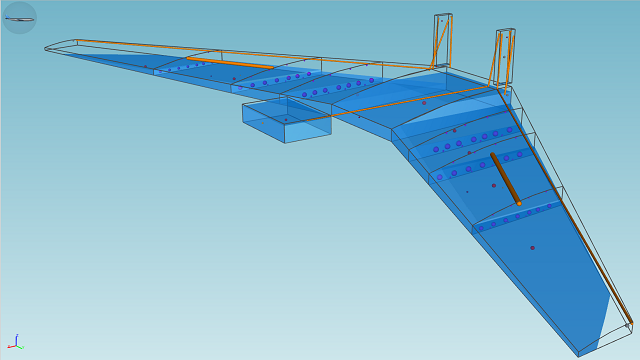

Aircraft Fuel System Simulation

Handle the challenging task of optimizing fuel pressurization, fueling, refueling and defueling of reservoirs with complex shapes while accounting for aircraft attitude, acceleration, wing bending or twisting. The software helps you model the venting, onboard inert gas generation system (OBIGGS), the fuel distribution network and the global energy management system in order to predict potential issues. You can improve efficiency, reduce weight, volume, and energy consumption of your fuel systems while satisfying certification requirements.

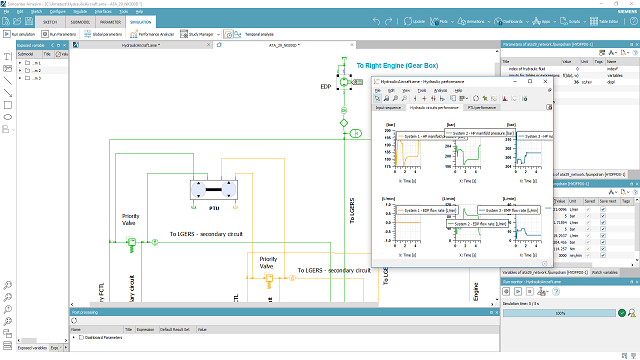

Aircraft Hydraulic System Simulation

Improve the performance of aircraft hydraulic systems by simulating their behavior for different sizing scenarios and flight missions. Simcenter Amesim provides a scalable approach to tackle engineering challenges ranging from low- to high-frequency dynamics. It allows you to integrate your hydraulic system models with those representing interfaced systems, such as electrical system, landing systems, and flight controls, to assess the aircraft performance at large. You can then estimate the system’s degraded performance by simulating how it responds to failures, and find alternative designs to meet certification requirements.

Fluid Power System Modeling

Assess the overall behavior of hydraulic or pneumatic systems and components. Simcenter Amesim comes with a set of predefined functional components for pumps, compressors, valves and actuators, as well as with a series of detailed geometry-based components. You can study the evolution of pressures, flow rates and temperatures in the complete system, and analyze the performance of specific components (valves or pumps), taking into account compressible flow, mixtures of gases, thermal effects, aeration and cavitation.

Heavy Equipment Actuation System Simulation

Design robust, reliable fluid power actuation systems for earthmoving, crane, crawler, mining equipment and more. Simcenter Amesim enables you to reduce power generation (such as variable displacement pumps and load sensing), develop new functions (such as self-leveling and control strategies) and improve product quality, robustness and reliability. The software enables you to consider every subsystem, and predict the dynamic behavior of the global fluid power system.

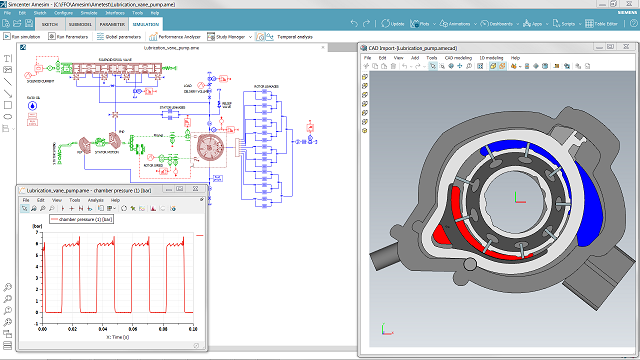

Pump & Valve System Simulation

Boost the performance of your compressors and hydraulic pumps with Simcenter Amesim. CAD import capabilities enable you to easily create a high-fidelity model from the detailed geometry. It helps you meet the increasing demand for high performance: flow characteristics, reduced pressure ripple and precise regulation of pump displacement. In addition, you can solve integration issues earlier in the design cycle, and optimize control strategies to adapt the pump flow according to the actual actuators’ request.

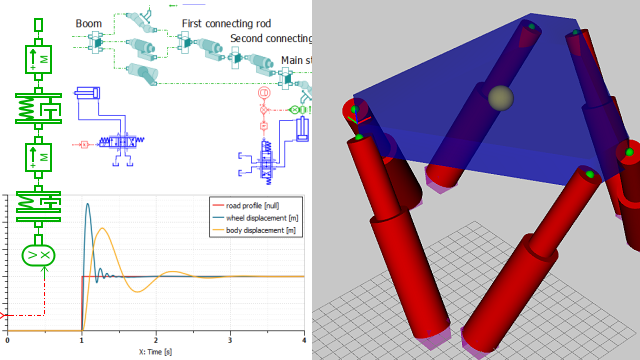

Mechanical System Simulation

Manage the increasing engineering complexity of mechanical systems. Simcenter Amesim includes state-of-the-art modeling techniques that allow multi-dimensional (1D, 2D and 3D) dynamic simulations.It enables you to study rigid or flexible bodies and complex non-linear frictions by analyzing low- or high-frequency phenomena. It takes into account contacts between complex geometries to increase reliability and robustness of developed kinematics. And it comes with multi-physics actuator models for accurate analysis of the coupling between mechanical structures and electric or hydraulic motion.

Simcenter Amesim allows you to frontload architecture and design decisions. The software comes with powerful modeling, analysis and optimization tools that help you virtually explore a large number of possible system architectures, predict performance, energy balance, noise and vibration behavior, and validate early in the design cycle the configuration that meet requirements. It also features connection between plant models and control models or code, to support the development of best-in-class mechatronic systems.

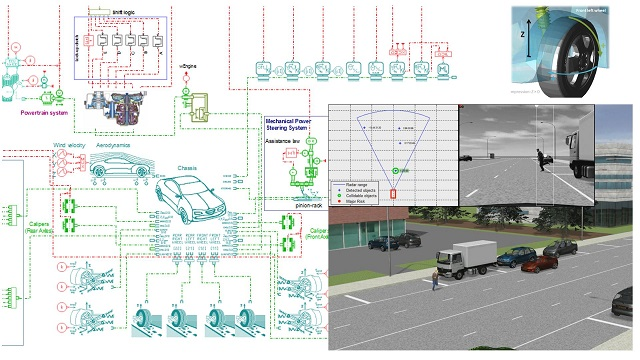

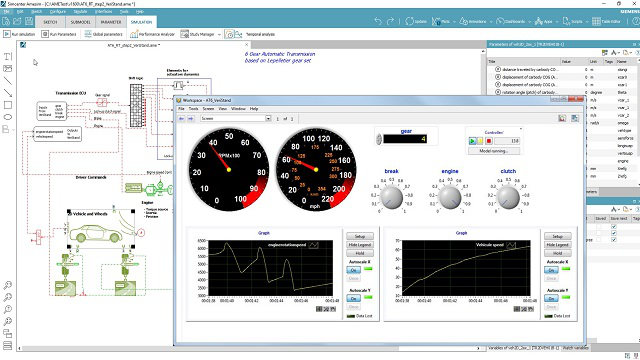

Powertrain Transmission System Simulation

Optimize the integration of any kind of transmission and vehicle to balance performance, fuel economy, drivability, comfort and reliability from the early design stages. Simcenter Amesim helps you improve fuel consumption by predicting losses, as well as reduce vibrations by detecting and modifying natural modes contributors, and reducing contact force variations, clutch judder, booming and clunk noise.

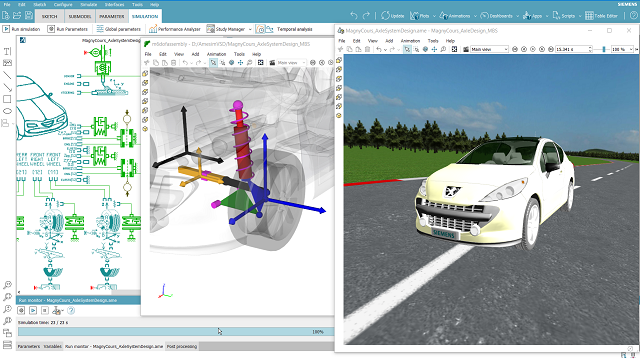

Vehicle System Dynamics Simulation

Effectively model vehicle systems, from the chassis itself to its related components, from early design to validation stages, and balance conflicting performance characteristics such as comfort, handling, stability, agility, drivability and fuel economy.

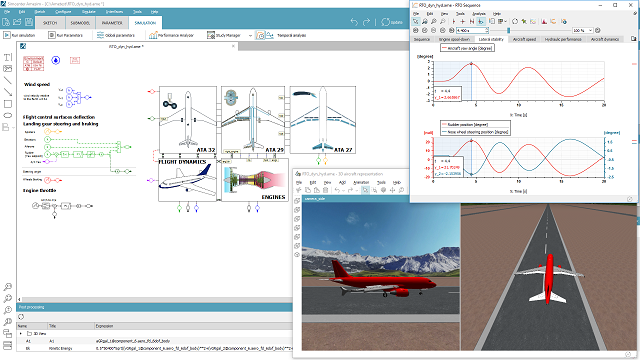

Flight Control System Simulation

Handle the multi-physics aspects of the entire flight control system for various actuation technologies, such as mechanical, direct drive, electromechanical or electro-hydrostatic. Simcenter Amesim covers the entire development process from predesign, to detailed dynamic analysis, and to real-time validation that considers the overall flight envelope. You can also integrate flight controls with interdependent systems to assess interactions earlier in the design phase.

Landing System Simulation

Design eco-friendly and cost-efficient landing gear systems, by reducing fuel consumption and carbon emissions during ground maneuvers. By using Simcenter Amesim from the early development stages to detailed analysis, system integration and validation, you can improve the reliability of landing gear systems, even for hard landing conditions, you can make the braking system more robust, even for a rejected take-off, and you can do a proper structural integration of extension and retraction systems.

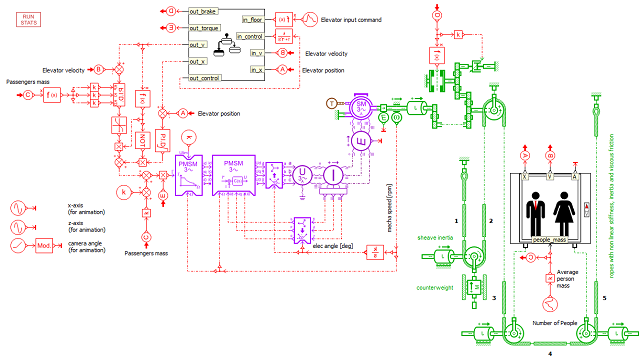

Mechanical System Modeling

Accurately model the kinematic and dynamic behavior of multi-body systems (from 1D to 3D) by using mechanical Simcenter Amesim components. Ready-to-use rigid or flexible bodies connected by functional junctions allow you to rapidly analyze a large number of effects, such as elastic collision, dry and viscous friction, worm gear, screw/nut, rack and pinion mechanisms, ropes and sheaves. Validated models of cams and followers help you seamlessly compare the performance of different hydromechanical valvetrain architectures.

Propulsion System Simulation

Develop the next generation of propulsion systems. The success of your future design will be critically influenced by propulsion technologies onboard. The increasing needs for performance, safety and efficiency cannot be met without integrating innovative propulsion architectures.

The multi-physics system simulation approach enables you to address the great variety of architectures and technologies. Powertrain electrification in automotive, reusable launch systems for the space industry or the use of alternative fuels (LNG) for ships are examples of technology implementation that modeling capabilities of Simcenter Amesim can support. You will be able to design and assess the impact of the propulsion system on various metrics such as onboard power generation or vehicle pollutant emissions, by performing a complete analysis of cross-system influences in a single platform.

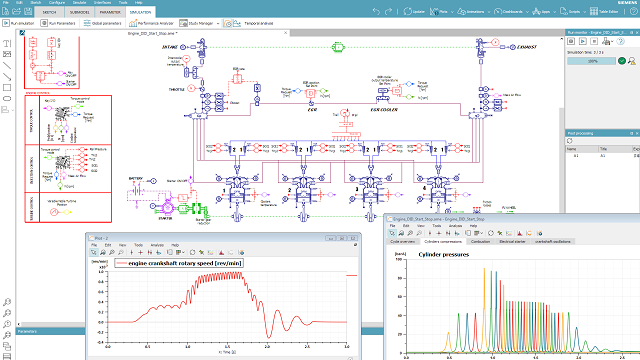

Internal Combustion Engine System Simulation

Design and optimize the complete internal combustion engine, including controls, and study integration with fuel injection subsystems, engine thermal management, electrical devices and powertrain components. You can also investigate alternative engine architectures and concepts.

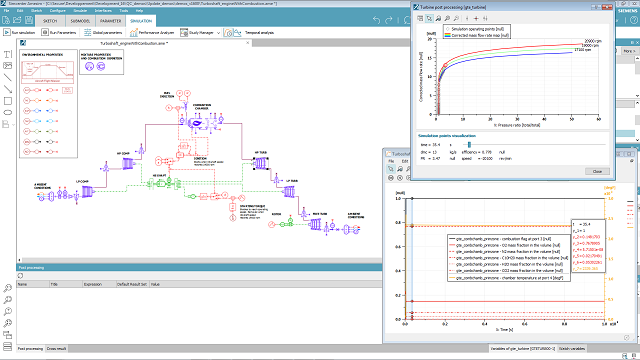

Aircraft Engine & Equipment System Simulation

Develop and balance the performance of conventional and innovative aircraft engine architectures by modeling and simulating their complete thermodynamic cycles in various operational conditions, accounting for environmental conditions, degradation of compressors and turbines, and by integrating their equipment and consumers. Simcenter Amesim enables you to integrate the best concepts early in the design cycle to assess the overall performance and to derive best fit-to-purpose engines. You can easily assess and realize your innovative ideas.

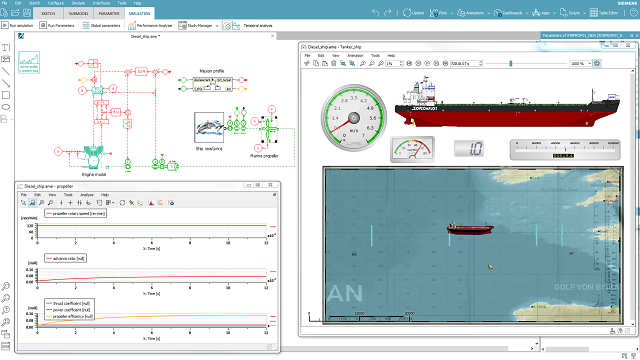

Marine Propulsion System Simulation

Optimize the hydrodynamic performance of your ship propulsion system by simulating multiple powertrain configurations, such as conventional, hybrid or electric battery, under different scenarios. Integrate your engine model and controls into the full ship architecture to estimate fuel consumption and NOx emissions for different load cases. Find the right compromise between accuracy and simulation time by coupling your Simcenter system simulation model with data from CFD calculations.

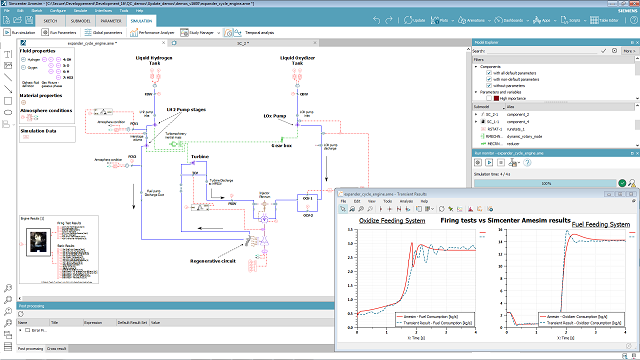

Space Propulsion & Subsystem Simulation

Challenge the performance of your space propulsion system by analyzing its transient behavior, during start-up and shut-down for instance. Simcenter Amesim enables you to optimize the engine performance by assessing different architectures of the complete engine and by evaluating various technologies for the different subsystems, like actuators, or their electrification. You can develop advanced controllers relying on predictive engine models, and evaluate the performance along missions by coupling the propulsion system with flight dynamics.

System Integration

Remove development silos and effectively handle increasing system complexity. If you want to successfully adopt model-based design (MBD), you need to apply a continuous modeling approach from early architecture design to the calibration stage. To support you in this engineering transformation, Simcenter Amesim offers a multi-level philosophy that allows you to gain efficiency by streamlining the user experience.

Versatility in terms of physical modeling, combined with dedicated unique features will help you set up the most effective engineering design process for a car, a plane, an excavator, a ship or any other industrial application. From components to the entire system, we offer you the tool that enables you to focus on your engineering challenge and address it as fast as possible with available data.

ADAS & Autonomous Vehicle Simulation

Validate advanced driver assistance systems and autonomous driving systems with models that include the correct vehicle dynamics and high-fidelity powertrain physics. Simcenter complements our Simcenter Prescan™ environment and sensor simulation solution, and makes you more effective in small to massive simulation activities, by providing off-the-shelf fidelity-scalable components. You always get the optimal balance between CPU time and accuracy, for safety, comfort, fuel and electrical energy consumption, and pollutant emissions assessments.

Complete Vehicle Simulation

Adopt a new engineering process that considers the complete vehicle and meet stringent legal and financial constraints. Simcenter Amesim helps you effectively deploy a model-based design approach. The software supports early design phases by allowing you to create simulation models for range and performance, and enables you later to create advanced vehicle energy management models, including predictive dynamic modeling of the engine, electric powertrain, battery, HVAC and all the associated thermal management systems.

Model-based Controls Development

Design high-quality controls in minimal time with Simcenter Amesim, from offline to real-time simulation. Indeed, developing a successful mechatronic solution requires optimizing the mechanics, electronics and software simultaneously as an integrated system. Therefore control strategy development is more than just creating logic flow diagrams. Some controller functions need advanced algorithms with deep physical insight and high-level mathematics. Accomplish this goal with advanced control techniques, such as model-predictive control (MPC) or neural network (NN).

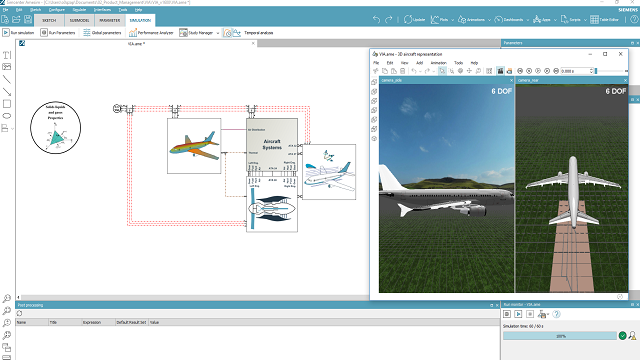

Virtual Integrated Aircraft

Increase the efficiency of your aircraft program by addressing the complexity of aircraft systems, and investigating system interactions from the early design phases. Simcenter system simulation solutions enable the virtual integrated aircraft (VIA) approach to support your model-based systems engineering, modeling and simulation, verification and validation processes. The approach can be tuned to the structure of your organization, and helps your engineering team collaborate, instead of work in silos.

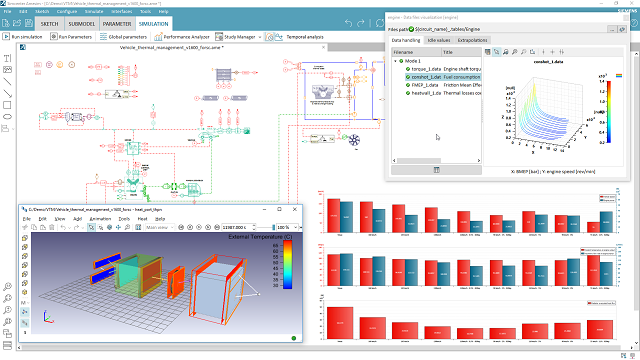

System Simulation Platform

Choose Simcenter Amesim and benefit from an open, powerful and user-friendly multi-physics system simulation platform to model, run and analyze complex systems and components.

The Simcenter platform is the core of the Simcenter software. With its powerful facilities, analysis and optimization tools, the solution offers an advanced and easy-to-use environment for 1D multi-physics system simulation and robust design.

Various scripting and customization capabilities provide seamless integration of Simcenter within your existing design processes. Being open and flexible, the Simcenter platform efficiently interfaces with many 1D and 3D computer-aided engineering (CAE) software solutions and helps you quickly derive and export models for standard real-time targets by providing a consistent and continuous model-in-the-loop (MiL), software-in-the-loop (SiL) and hardware-in-the-loop (HiL) capable framework.

Productivity

Boost the return you get from your simulations thanks to a set of powerful features which guide you in model-based systems engineering processes. Advanced pre- and post-processing tools allow you to gain in-depth information regarding your systems. You can customize your model processing and analysis using easy-to-configure apps. Optimization and design exploration capabilities allow you to get your system configured right the first time. Simulator scripting helps automate a large part of your simulation activities.

Technologies

Perform advanced simulations by leveraging the best-in-class simulation technologies of the Simcenter integrated platform. Be it for high-performance computing (HPC) or real-time simulation, you can create, analyze, deploy and run your multi-physics models almost anywhere. Ultimately, the support of recognized standards like the Functional Mock-up Interface (FMI) or Modelica and its many software interfaces, make Simcenter one of the most interoperable platforms on the market.

Workflow

Experience Simcenter as a collaboration framework facilitating a company-wide, consistent implementation of system simulation technology. Key aspects are customization, automation, integration for all your vertical applications. It is fully integrated into your CAD, CAE or PIDO processes within your enterprise. Import any third-party software to reuse your models, analyze and explore designs. Ensure the data continuity from CAD and experiments to system simulation. You can address myriad engineering challenges based on your existing workflows.

Thermal Management System Simulation

Design efficient and reliable systems by optimizing thermal management. Keeping the temperature of components within the optimal operating range, evacuating excess heat or reusing it to improve performance and efficiency has become an inherent challenge for today’s complex systems. To help you address thermal integration issues, Simcenter Amesim offers you a comprehensive set of solutions that cover the whole design cycle from predesign stage to final validation.

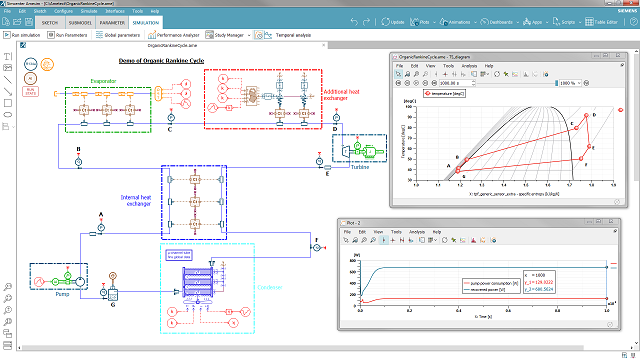

Simcenter Amesim helps maximize thermal performance such as comfort in cars, planes or rooms, while optimizing energy efficiency. You can use the software to represent the real operating environment of your system, including interactions with surroundings when designing and validating your temperature control strategies. Additionally, Simcenter Amesim enables you to study the integration of energy recovery systems and their impact on performance and energy consumption. You can also benefit from the advanced post-processing features to graphically visualize energy flows in your system.

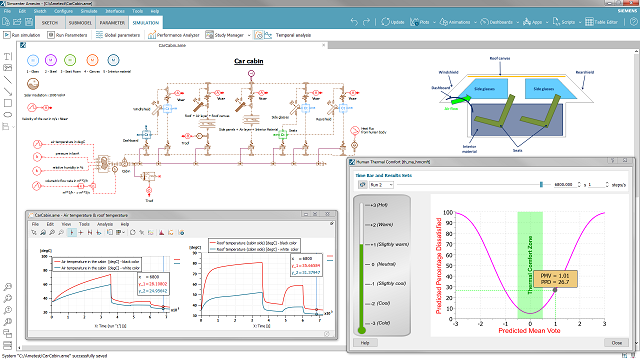

HVAC & Vehicle Cabin Comfort Simulation

Study and optimize the design of air conditioning loops or heat-pump systems, evaluate the cabin cool down or heating processes, check the impact of exterior conditions and technological choices on the air temperature and humidity in the cabin, and assess human thermal comfort sensation.

Electric Vehicle Thermal Management System Simulation

Optimize range and cabin comfort by managing thermal energy while keeping under control the temperature of critical subsystems such as the battery or the electric motor. Simcenter Amesim enables you to model electrical and thermal aspects of every car subsystem. Thanks to tight integration with Simcenter STAR-CCM+™ computational fluid dynamics (CFD) technologies, you can benefit from advanced heat exchanger stacking analysis.

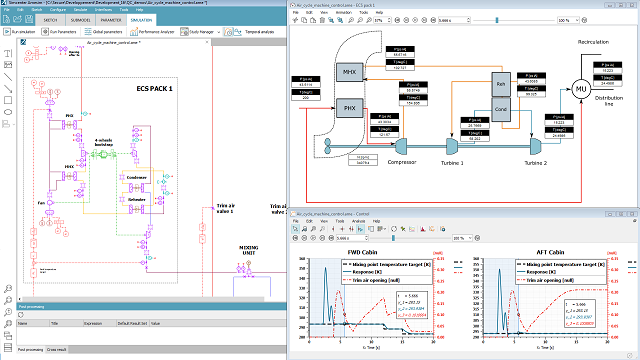

Environmental Control Systems

Ensure the comfort of passengers and crew in aircraft, ships, submarines, trains and battle tanks. Simcenter Amesim helps design the cabin, bleed system control, global energy management, air conditioning, ventilation circuit and carbon dioxide bottle discharge systems. The solution enables you to take into account temperature, humidity, pressure and change of pressure rate in dynamic conditions. It helps you design systems with higher efficiency, lower weight and volume, and reduced energy consumption.

Thermodynamic System Modeling

Model any type of thermal management systems by simulating heat transfer between solids, liquids, and gas as well as phase change phenomena with Simcenter Amesim. Benefit from a comprehensive set of components such as pumps, thermostats or heat exchangers to accurately study the transient behavior of your system. Simcenter Amesim enables you to size components and compares different architectures or control strategies while accounting for thermal interactions between different subsystems.

Vehicle & Engine Thermal Management System Simulation

Combine maximum thermal safety with high energy efficiency. Simcenter Amesim helps you ensure the engine is correctly cooled down by optimizing heat-exchangers, pumps and thermostats. Optimize warm-up phases, control strategies and integration with the HVAC system, all in a single, user-friendly simulation environment. You will even be able to evaluate disruptive technologies such as phase change materials or advanced heat recovery systems.