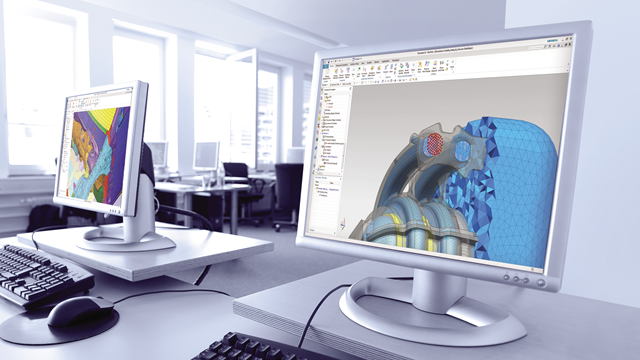

Simcenter™ 3D software is a unified, scalable, open and extensible environment for 3D CAE with connections to design, 1D simulation, test, and data management. Simcenter 3D speeds the simulation process by combining best-in-class geometry editing, associative simulation modeling and multi-discipline solutions embedded with industry expertise. Fast and accurate solvers power structural, acoustics, flow, thermal, motion, and composites analyses, as well as optimization and multi-physics simulation.

Simcenter 3D is available as a standalone simulation environment. It is also available completely integrated with NX delivering a seamless CAD/CAE experience.

Structural Simulation

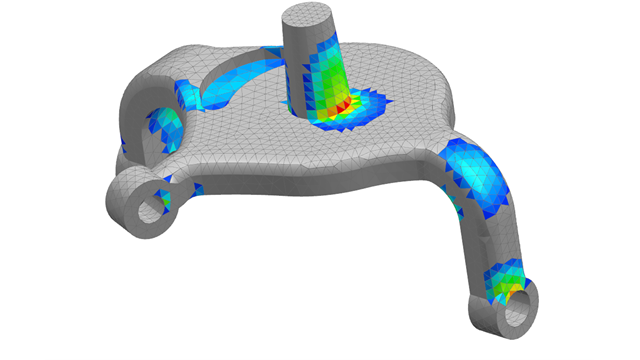

Understanding how a component or product assembly reacts under stress or vibration is critical in any industry, but as products and materials become increasingly complex, engineers need tools that go beyond linear statics analyses. Simcenter includes the structural solutions you need for a wide range of structural analysis problems within a single user environment. You no longer need one tool for linear statics, another to study fatigue, and yet another for nonlinear analysis. As a result, engineering departments can consolidate analysis tools, and you only need to know a single user interface.

Composites

In the quest to make products lighter yet stronger, manufacturers are increasing their use of composite materials. It is also prohibitively expensive to create prototypes of products made from composites, so simulation must play a key role in the development of new products using laminate composite materials. Simcenter is at the leading-edge of composites analysis through continuous development of material models and element types. Simcenter speeds the entire process for simulating laminate composite materials through a seamless connection to composites design, accurate solvers and comprehensive post-processing.

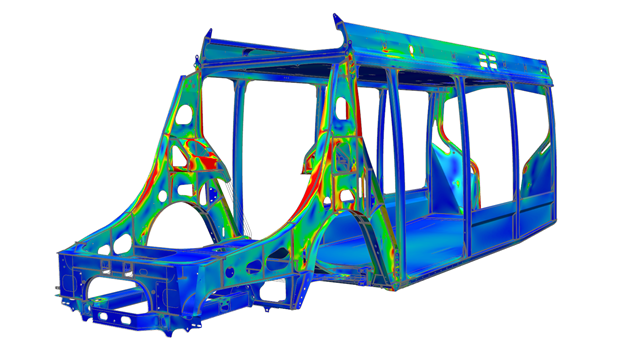

Durability Simulation

Undoubtedly the most challenging task for durability engineers is designing fail-safe components and systems in the most efficient manner. System parts with insufficient fatigue strength may cause permanent structural damage and potentially life-threatening situations. Mistakes can cause product recalls which negatively influence not only the product but the overall brand image. Shorter development cycles and ever-increasing quality requirements have stretched test-based durability approaches to the limits. Evaluating and refining the durability performance by simulation methods is the only valid alternative.

Simcenter gives you access to state-of-the art analysis methods that enable you to perform fatigue life prediction analyses quickly and accurately accounting for realistic loading conditions.

Motion Simulation

Understanding the operating environments for intricate mechanical systems – like in wing flaps or landing gear, sliding sunroofs or suspensions, or photocopiers and other mechanisms – can be challenging. Motion simulation calculates the reaction forces, torques, velocities, acceleration and more for mechanical systems. You can directly convert CAD geometry and assembly constraints into an accurate motion model or create your own motion model from scratch, and the embedded motion solver and robust postprocessing capabilities allow you to study of a broad range of product behaviors.

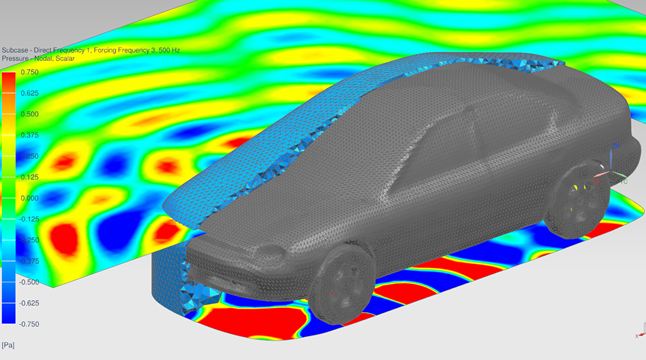

Acoustics Simulation

Acoustics analysis can help you conquer these challenges. Simcenter offers interior and exterior acoustic analysis within an integrated solution that helps you make informed decisions during the early design stages so you can optimize your product’s acoustic performance. A unified and scalable modeling environment combined with efficient solvers and easy-to-interpret visualization capabilities enable you to quickly gain insight into the acoustic performance of your product.

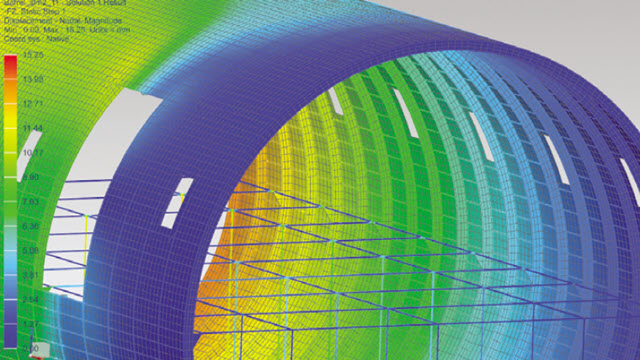

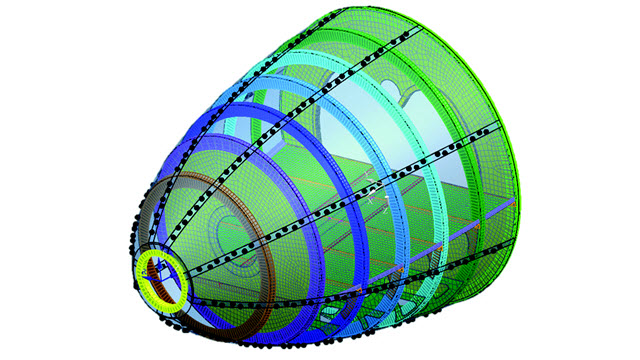

Aerostructures Simulation

Simcenter can help you meet shorter timelines and reduce structural analysis costs with the ability to perform end-to-end aerostructure assessment in a fully integrated environment. Eliminate mistakes and ramp up productivity with ready-to-use failure prediction methods and customize your solution by integrating your internal tools and IP to streamline your aerostructures analysis processes.

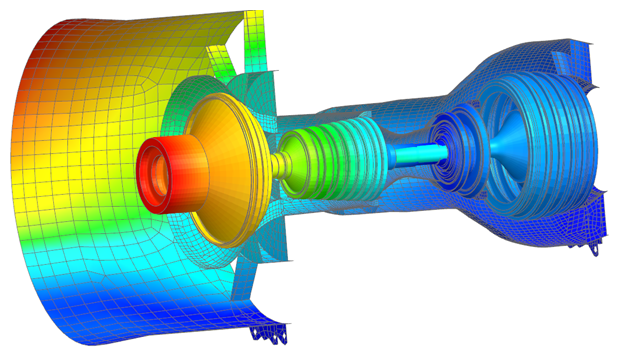

Dynamics Simulation

Most machines and vehicles experience vibrations and other excitations that can impact their structural performance. Historically, physical testing methods have been used for understanding the structural dynamics of various products. However, testing is costly and time consuming, and perhaps not very feasible with large structures like aircraft or ships. Simulation has become a key technology in understanding the structural dynamics for automobiles, spacecraft, jet engines, ships, electronic devices and industrial machines.

Simcenter offers a comprehensive solution to understand, analyze and improve the response when a system is subjected to dynamic loading. Simcenter builds on over 50 years of dynamics analysis experience to offer you the ability to efficiently understand and avoid excessive vibrations and stresses. Dedicated capabilities are available for noise, vibration and harshness (NVH) engineering, rotor dynamics and correlation.

Multiphysics Simulation

An uncomfortable truth about modern engineering is that there really are no easy problems left to solve. In order to meet the demands of industry, it’s no longer good enough to do ‘a bit of CFD’ or ‘some stress analysis’. Complex industrial problems require solutions that span a multitude of physical phenomena, which often can only be solved using simulation techniques that cross several engineering disciplines.

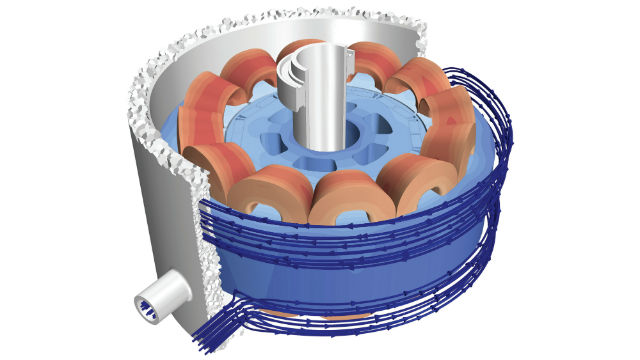

Electromagnetic Simulations

The diverse and increasingly significant role of electromagnetics in product development and design brings new challenges. In this regard, committing to deliver products that are higher in efficiency, reliability, compatibility, and durability starts with comprehending how these complex fields and waves behave and change.

Simcenter includes distinct low and high-frequency electromagnetic simulation capabilities for the unique demands in each domain. Expand your insight into the performance of electromechanical components, energy conversion, design and siting of antennas, electromagnetic compatibility (EMC) and electromagnetic interference (EMI). A range of dedicated solvers (time and frequency based, linear and nonlinear, finite and boundary element) offers a transformative CAE process, with simulations ranging from a fast, initial analysis to inherent realism for final verification.

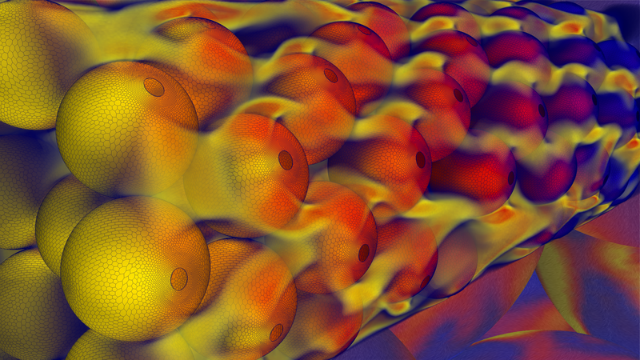

Fluid dynamics simulation

Simcenter provides industry leading computational fluid dynamics software that allows you to simulate almost any engineering problem that involves the fluids, structures and all of the associated physics.

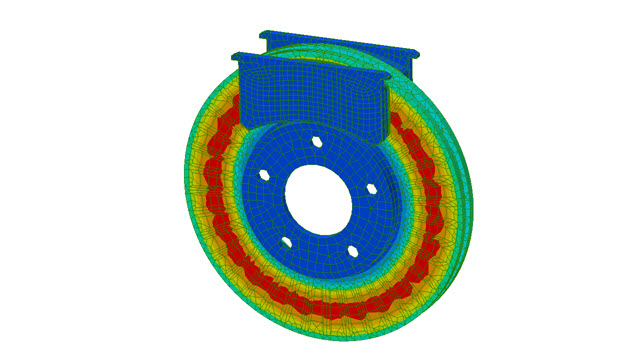

Thermal Simulation

Thermal management is a major consideration for a wide range of products, including industrial machinery, automobiles and consumer electronics. The objective of any thermal management solution is to maintain a product’s temperature within a range that is optimal for performance. Accomplishing this may require the removal or addition of heat, either passively or in an actively managed fashion, and this can be evaluated using thermal simulation software.

Simcenter includes comprehensive, best-in-class thermal simulation capabilities that can help you to understand the thermal characteristics of your product and subsequently tailor your thermal management solution for optimal performance.

Meshing

Efficiently mesh your models using extensive modeling functions for automatic and manual mesh generation of 1D, 2D and 3D elements in addition to numerous techniques for the application of loads and boundary conditions. User-defined geometry edits, mesh and boundary conditions are all associated to the base design, which means when the base design geometry changes, you can rapidly update your model. This approach greatly reduces downstream modeling time, which results in huge time savings across a project’s many design-analysis iterations.

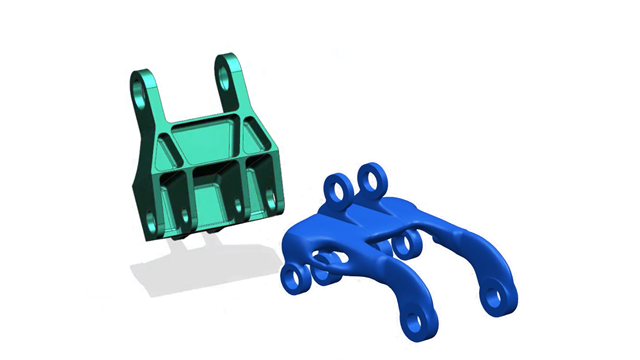

Optimization

How can I reduce material in a component or change its properties while ensuring it continues to meet performance targets? Simcenter delivers engineering optimization techniques that can help you answer these this question by systematically searching for the best design that satisfies certain criteria. Reduce component weight or find the right combination of parameters to improve product performance through comprehensive topology, geometry, and parameter optimization capabilities.

Pre / Postprocessing

Reduce the time you spend preparing analysis models, and spend more time evaluating results. Quickly move from multi-CAD geometry data to a complete, run-ready analysis model using unique tools for CAE geometry editing, comprehensive meshing, FE assembly management, multi-CAE solver environments, and fast simulation results post processing and reporting.

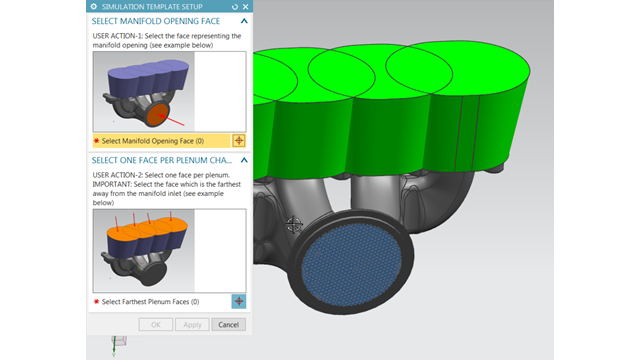

Simulation Automation & Scalability

As companies increase their reliance on simulation, they are seeking ways to speed-up the analysis process and increase simulation throughput. One way to increase simulation throughput is to capture repetitive CAE processes, standardize them, and then automate them. Simcenter allows you to capture the expertise of senior analysts and make it available for junior engineers in your organization to use in the form of wizards or templates.