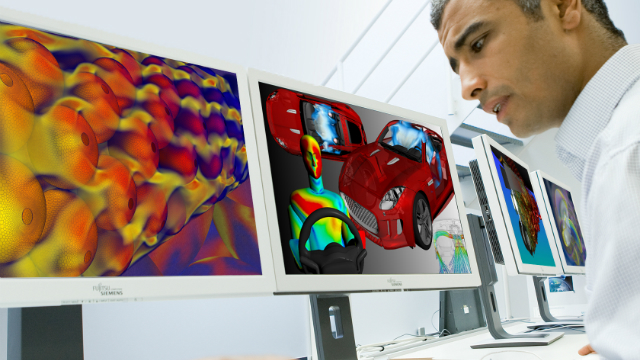

Simcenter™ Flotherm™ software creates a thermal digital twin of an electronics product that is capable of simulating temperature and airflow. A thermal digital twin is easily created for any electronics product by working with SmartParts™ (heatsinks, fans, enclosures, TECs, PCMs, are more) and a customizable part library system.

Additionally, geometry from all MCAD systems can be imported and efficiently converted into SmartParts. Support for standard EDA formats like ODB++ allows the thermal digital twin to stay in sync with any PCB layout tool present in the design flow.

Simcenter Flotherm’s Instamesh™ Cartesian-based grid system is created instantly and consistently for any digital twin, even those that include many thousands of parts. The Instamesh system enables the thermal engineer to explore the design with Command Center (built-in parametric and optimization module) free of grid quality concerns.

Automatic calibration using Simcenter T3STER™ transient measurements underpins the thermal digital twin accuracy (typically 99+%).

Modeling of basic geometric shapes: Provides modeling of basic shapes such as cubes, prisms, cylinders, spheres, and inclined plates;

Modeling of typical electronic devices: Provides the establishment of parametric models of common devices in electronic equipment such as chassis, fans, radiators, filters, heat exchangers, heat pipes, cold plates, and TEC (semiconductor refrigerators);

Simplified model establishment: The model can be simplified. The software provides a thin plate heat conduction model and a thermal resistance-heat capacity network model, as well as the establishment of heat source and damping models. The heat source characteristics and damping characteristics of the device are input for simulation;

Advanced Zoom-in function: The advanced Zoom-in function can use the calculation results of the upper-level model as the boundary condition of the lower-level model calculation, so that the model calculation results are transferred layer by layer, from the system level to the subsystem level, simplifying the calculation process and reducing the workload, thereby Greatly reduce the model analysis time.

Robust grid and fast solver: Flotherm allows engineers to focus on design and provide the most accurate results possible during the project schedule. Its Smartparts structured Cartesian method provides the fastest resolution time for each grid cell. Flotherm's "local grid" technology supports integration, nesting, and non-conformal grid interface solutions between different parts of the field.

Usability and smart thermal model: Checking the overall model in Flotherm allows users to see the connection material of the object, the ability to connect to each object, and the corresponding component-level power consumption. It also identifies whether the object is creating grid lines. Flotherm SmartParts represents the entire IC electronics rack from a large list of suppliers, simplifying model building time and minimizing the accuracy of the solution.

Analysis of thermal characteristics of components and systems: Flotherm is combined with electronic thermal simulation of transient thermal characteristics of T3Ster. Since the reliability of components can reduce thermal problems, using T3Ster allows manufacturers to design chips, integrated circuits, printed circuit boards and superior thermal performance. They can also publish reliable thermal data for downstream applications.

Transient analysis: It has the function of transient analysis of changing power consumption and changing environment. It can not only perform transient analysis of startup, shutdown, and failure, but also perform transient analysis under changing power consumption and environmental changes; transient power Consumption and its temperature response

Radiation calculation: It is currently the only electronic heat dissipation simulation software that can use the high-precision Monte-Carlo method for radiation calculation, which is very suitable for the calculation of enclosed equipment and outer space electronic equipment;

Liquid cooling analysis: It can analyze the heat dissipation system containing multiple cooling media, such as the thermal analysis of electronic equipment or cold plates with liquid cooling and air cooling at the same time;

Convergence criteria: Flotherm defines strict convergence criteria for the application of CFD software in the field of electronic thermal simulation. A good convergence criterion must meet: to ensure reliable convergence, that is, if the software considers convergence, it should get a true and reliable solution. Need to rely purely on human experience to judge the reliability of the results. Flotherm software perfectly fulfills the above requirements.