To accurately predict real-world performance of your product you need simulation tools that capture all of the physics that will influence its performance during its operational life, including those that cross the boundaries of traditional engineering disciplines. To improve your product you need to be able to predict how performance changes in response to multiple parametric design changes.

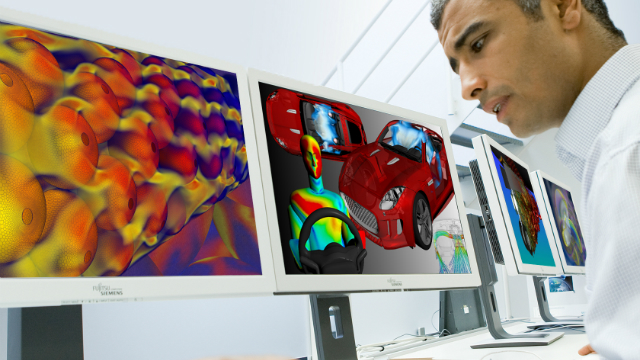

Simcenter™ STAR-CCM+™ software is a complete multiphysics solution for the simulation of products and designs operating under real-world conditions. Uniquely, Simcenter STAR-CCM+ brings automated design exploration and optimization to the simulation toolkit of every engineer, allowing you to efficiently explore the entire design space instead of focusing on single point design scenarios.

The additional insight gained by using Simcenter STAR-CCM+ to guide your design process ultimately leads to more innovative products that exceed customer expectations.

Electrochemistry Simulation

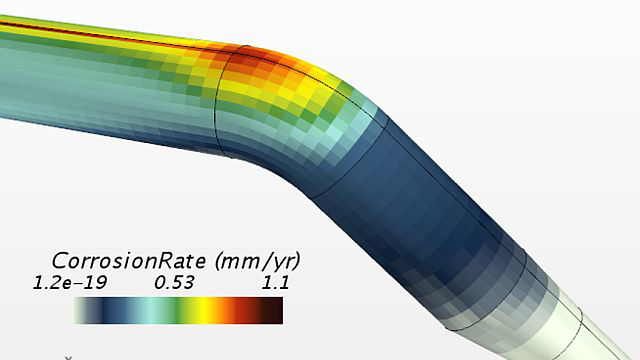

Our comprehensive electrochemistry simulation suite includes the building blocks of electrochemistry, various degrees of fidelity, tailor-made electrochemistry models, multiphase electrochemistry and design exploration capabilities.

With electrochemistry simulation in Simcenter, you can achieve decreased resistances, minimize degradation and attain higher deposition/etching rates. This lowers design/operational/maintenance costs while ushering in innovative new fuel cell types, operating ranges and novel processes and materials.

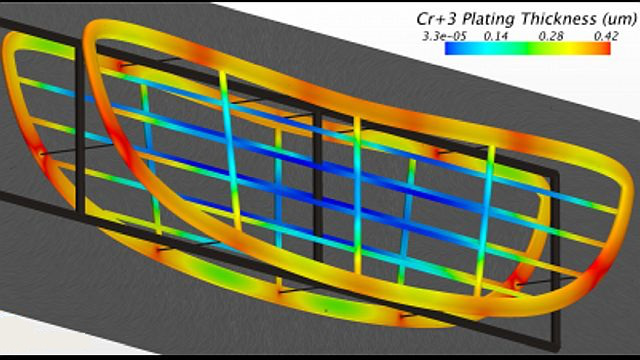

Application-specific Electrochemistry Models

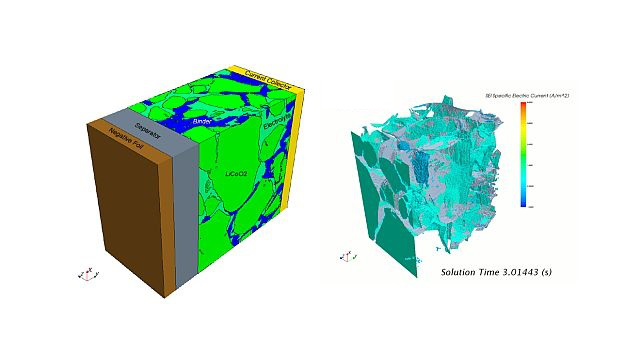

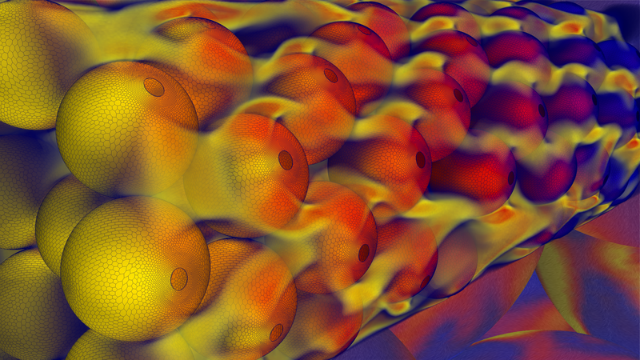

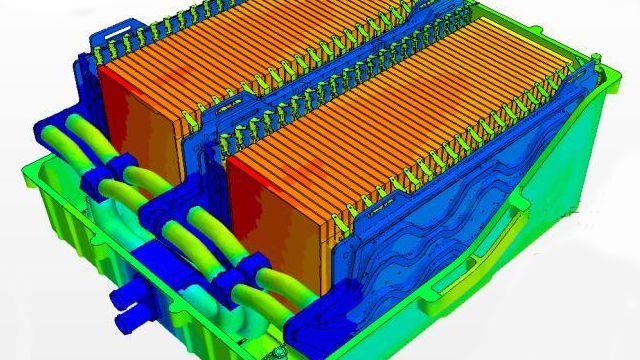

Simcenter includes tailor-made electrochemistry models for various applications. The electrodeposition coating model offers identification and remedying of positions with no or too thin coating in body-in-white manufacturing processes optimizing manufacturing spend and time. The Li-ion battery model helps simulate the design and analysis of microstructural topology of such batteries to understand performance factors and predict risk of dendrite growth.

Electrochemistry Multiphysics

Products aren’t designed in isolation and multi-physics products require multi-physics simulations. Utilize tight coupling between your electrochemistry models, flow and energy to simulate the correct real-world electrochemical behavior between species in any multi-component phase and ions in adjacent solid or between ions/electrons in solid porous phases and multi-component fluid species.

Flexible and Generic Electrochemistry Models

Simcenter offers the building blocks of complete electrochemistry simulation in one tool, bringing electromagnetism, electrochemical reactions and species, bulk ion chemical reactions and coupled plasma electron simulation together. Combine models to achieve required level of fidelity and understand real-world behavior of electrochemical applications including fuel cells, electroplating, wet etching, corrosion and plasma enhanced CVD (PECVD)

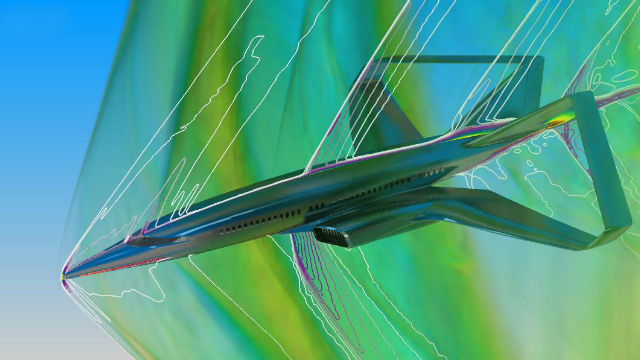

Fluid dynamics simulation

Since the real-world performance of your product depends on how it interacts with fluids, either gases, liquids or a combination of both, you need to predict how those fluids behave, and to be able to turn their influence to your product's advantage.

Simcenter provides industry leading computational fluid dynamics software that allows you to simulate almost any engineering problem that involves the fluids, structures and all of the associated physics.

Moving Objects

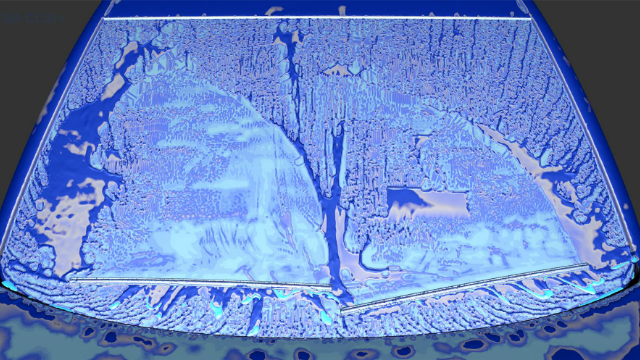

Problems that involve multiple moving and interacting components can be easily simulated using overset meshing, mesh morphing, or a combination of both. The moving mesh capabilities can also be used for parametric studies and for steady or unsteady simulations, providing an easy way to reposition or replace objects to study multiple design configurations.

Multiphase Flow

Accurately representing the physical behavior of the different fluid and solid phases is key to capturing the real-world performance of your product. Simcenter offers a variety of both Eulerian and Lagrangian modeling capabilities to suit your simulation needs.

Particle flows

The discrete element method (DEM) can be used to simulate the motion of a large number of interacting discrete objects (particles), such as the granular flow of aggregates, food particles, metal powders, tablets and capsules, and wheat or grass. Simcenter is the first commercial engineering simulation tool to include a DEM capability that is fully coupled with numerical flow simulation.

Reacting Flow

Gain insight into the interactions between turbulent flow field and underlying chemistry of reacting flows. Simcenter helps you improve the trade-off between the performance and emissions of your device for different operating conditions.

Rheology

Computational rheology is used to model non-Newtonian or viscoelastic materials in industrial problems. The rheology solver accurately resolves the dominant physics of complex rheological material flow and helps predict their behavior.

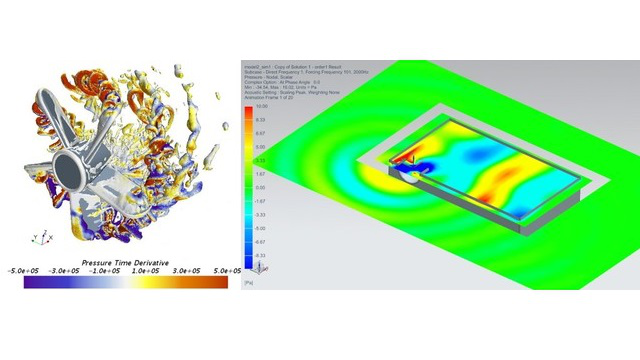

Aero-acoustics

Flow induced noise is a significant component of the acoustic signature of a vehicle (or other product). Simcenter offers an extensive library of accurate models for predicting aeroacoustics noise sources, including: steady state models, direct models (DES/LES), propagation models and acoustic perturbation equations (APE) solver.

Simcenter supports hybrid aero-acoustic methods in which at first, a CFD simulation is used for capturing flow turbulences, which are translated into aero-acoustic sources to be plugged into a second acoustic (FEM) simulation model. The latter then predicts the acoustic propagation of these sources, including reflections and absorption in the environment. As such, for instance the cooling noise of electronic equipment of the HVAC noise in a car can be predicted.

Battery Simulation

Digitally validate Li-ion cell design including geometrical cell specifications and cell performance. Extensive components of a battery cell are available, as well as a material database to support the user in its model development.

Co-simulation

Couple to other simulation tools through dedicated interfaces, or an intuitive API. This enables the multi-physics simulations with different time scales ranging from microseconds to thousands of seconds, providing faster and more accurate analyses and shorter turnover times for development and assessment of complex designs

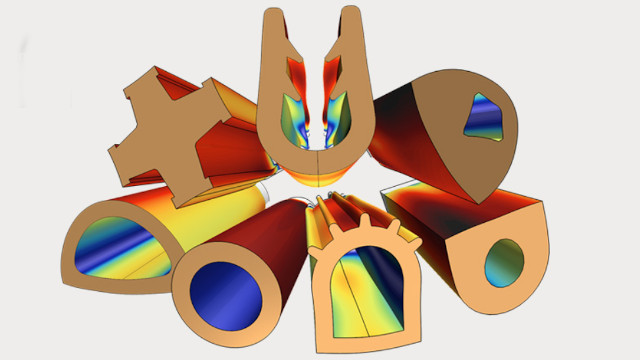

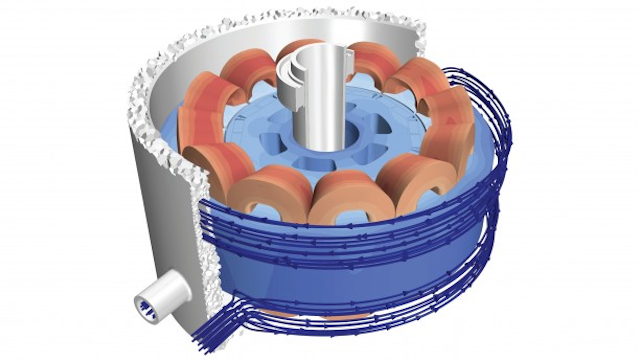

Electric Machines

Comprehensive analytical models include all aspects of the design of electric machines, including thermal, electromagnetic and drive control. Of particular importance is the efficient utilization, and even elimination, of magnets. Our simulation tools are structured to give seamless design capability over the entire range of permanent-magnet machines and the alternatives including hybrid combinations and covers the entire range of power, voltage, and speed used in vehicle systems.

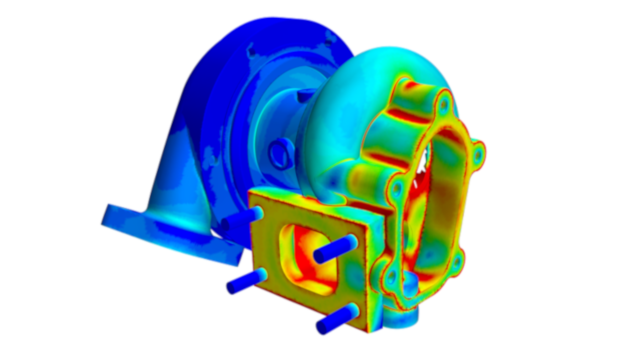

Engine Simulation

Engine simulations involve moving components, multiphase flow, combustion and heat transfer. You no longer have to be an expert user to simulate internal combustion engines: using an application-specific workflow and simplified interface allows you to set up engine simulations quickly and easily. Expert users can use those simulations as the starting point for performing more complicated multiphysics engine simulations that exploit the full range of Simcenter STAR-CCM+ simulation capabilities.

Fluid dynamics

The computational fluid dynamics (CFD) capability in Simcenter offers an efficient and accurate set of fluid dynamics models and solvers with excellent parallel performance and scalability. It provides a solid foundation for multidisciplinary design exploration.

Solid Mechanics

Almost all real-world engineering problems ultimately depend on the interaction between fluids and solid structures. Simcenter STAR-CCM+ offers both finite volume (FV)-based computational fluid dynamics and finite element (FE)-based computational solid mechanics (CSM) in an easy-to-use single integrated user interface. Using this approach you can solve static, quasi-static, and dynamic problems including those with nonlinear geometry and multiple parts using bonded and small sliding contacts.